Description

The installation method of steel gratings

There are two kinds of method for connecting gratings and supporting beams:

Welding: to weld gratings on the supporting beams. In order to prevent the risk of dropping, try to use welding method to fix gratings.

Installation clips: using clips to fix gratings to the supporting beams. Except for the occasion demands moving frequently, it is not recommended to use clips to install gratings for safety. If it is necessary to use clips, it is recommended to inspect the fixing status of clips at all times.

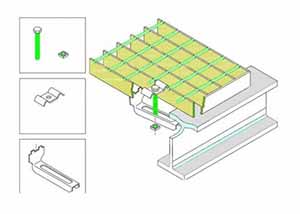

The steel gratings shall be installed as per the structural slab construction, after installation, the gratings can not be moved or to come apart from the supporting beams at casually. The length of both ends on the supporting beams along the flat bearing bars of gratings shall not be less than 25mm. The installation shall be carried out strictly according to the arrangement plan of gratings. Before installation, it is necessary to read the specifications of the arrangement plan, so that to ensure that the model, bearing direction as well as the installation clearance are correct. Due to the tolerance during manufacturing, the actual dimensions may be a little different with the designed dimensions. In order to ensure the beauty of the whole installation, it is recommended to adjust the installation clearance evenly. The specific installation method shall be as customers’ requirement, and gratings shall be installed on the supporting beams by welding method or by using installation clips. Welding provides the most reliable and permanent connection. When gratings are required frequent removal or it is not allowed to damage the surface coating, it is recommended to use clips and we can supply clips as required.

Welding

For the occasions that it is not required to move gratings frequently, it is recommended to use welding method to install gratings to form a reliable and permanent connection. The usual welding position is showed as the figure (there should be one spot welding at positions between two flat bearing bars). But when welding at site, in order to reduce spattering, it is often to make full welding at overlap of four angles on the supporting beams (when the width of gratings is more than 500mm, in order to ensure the safety, it is recommended to make a welding at the middle position along the width direction). The height of welding bead shall be 4mm. after completing welding, the weld flux and metal spatters shall be removed, and anti-rust paint (the color shall be similar to the surface of grating) shall be applied by hand at beads.

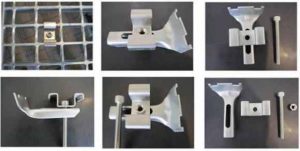

Installation clips

Clips are recommended to use when gratings are subject to frequent removal. For each piece of grating, it is recommended to use four clips at least, and for the larger size gratings, the number of clips may be increased as per the actual condition. When the customer has no special requirement, the clips will be supplied as per four numbers of each piece of grating. The clips are divided into two classifications: the upper clips and the upper & lower clips. Both classifications include bolts, nuts and washers. The installation method of the upper clips is to weld the head of bolt on the supporting beam, and use a normal spanner to tighten the nut, then the upper clip can be fixed. The installation method of the upper and lower clip is to click the toothed part of elevation of the lower clip to the bottom of grating, and the other end is clicked on the supporting beam, then using an Allen key to tighten the Allen bolt at the upper part of grating, thus the clip can be fixed. Due to the limitation of dimension as well as the structure of supporting beam, there is a certain limitation in using clips method. So, the clip method is subject to both parties’ negotiation.